Conversion of conventional hydraulic surface grinder

Category : Articles

As everyone is aware , the surface grinder uses hydraulic system for reciprocation . Apparently it seems a very simple system only with one double piston rod cylinder with reciprocating action and working at a very low pressure . However only the designers and the maintenance team know how complicated the system is ! Whenever there is break down it becomes really tough job for maintenance team since there are no standard valves used in the circuit except may be a relief valve. All other valves like the direction control valve, flow control valve, deceleration valve etc. are specially manufactured and fitted in a single manifold block by the machine manufacturers . Unless the maintenance person has a thorough knowledge of hydraulics it becomes very difficult to even recognize the components and trace the circuit. Most of the flow control, DC valves are fine tuned by the manufacturer so as to avoid any vibrations or jerks during the reversal. Jerk free movement is very crucial to the operation of surface grinder. Hence trouble shooting of this type a circuit becomes a tough task. It’s not only tough but it consumes too much of time. The spare valves are never readily available as these are specially made for the application by the machine manufacturer and the user has no choice but to contact the machine manufacturer.

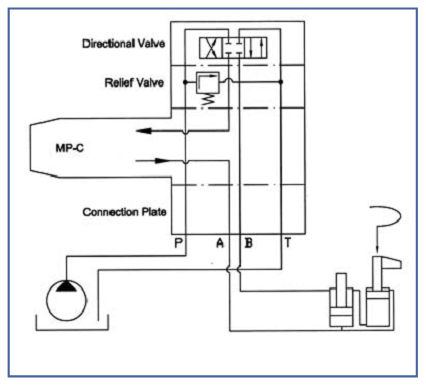

Avoid this ! Go for a proportional valve system. The pump, motor and accessories remain the same. A standard NG06 or NG10 size simple open loop proportional valve works like a combination of direction control, flow control and deceleration / acceleration control valves. This becomes the most simplified system. A small change in control panel is needed which can generate a signal of +/- 10V. Reversal signal can be generated by a simple limit or proximity switch. This eliminates the need of complicated cams, dogs, throttle valves etc. All the parameters like maximum speed, acceleration / deceleration values can be controlled on a control panel with potentiometer and a small PLC . In addition, if one uses a low pressure variable volume vane pump then there can be a substantial reduction in the power consumed and heat generation.

Conclusion – conversion to proportional valve system 01. Reduces down time 02. Circuit can be understood easily 03. Ready availability of spares since all valves used are manufactured by standard hydraulic companies 04. Results in lower inventory carrying costs

Go for it !