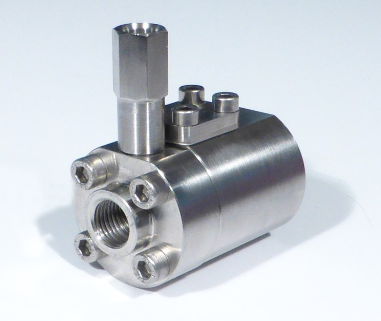

2-2 Directional Valves

Available in both normally open and normally closed configuration, the 2/2 valve is supplied as a cartridge design and therefore can be arranged to offer multiple functions from a single block, reducing cost on expensive fittings and pipe work.

Applications :

Hydraulic power units in Nuclear Industry, Naval, Oil & Gas sector, Mining Industry, Water Treatment Plants, Desalination, Fire Protection Equipments, Food Industry Machinery.

- Flow Range : 0-10 lpm.

- Operating Pressure : Max. 160 Bar

- Inlet Pressure : Max. 200 Bar

2-2 Pilot Valves

Available in both normally open and normally closed configuration, the 2/2 valve is supplied as a manifold design and therefore can be arranged to offer multiple functions from a single block; reducing cost on expensive fittings and pipe work. The pilot section wet pin design solenoid actuator has no dynamic sealing and therefore produces adequate force to directly actuate the valve with an orifice size of 2.5mm up to a maximum working pressure of 160 bar.

Applications :

Hydraulic power units in Nuclear Industry, Naval, Oil & Gas sector, Mining Industry, Water Treatment Plants, Desalination, Fire Protection Equipments, Food Industry Machinery.

- Flow Range : DN9 : 0-60 lpm., DN25 : 0-120 lpm.

- Operating Pressure : 8 to 160 Bar

- Inlet Pressure : Max. 200 Bar

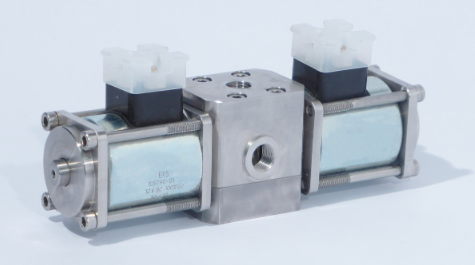

4-2/3-2 Directional Valves

A patented range of valves which control the directional flow of corrosive fluids in hydraulic systems. Designed specifically for fluids with low viscosity, the valves offer high efficiency with minimal energy input for actuation. Available in 4/2 & 3/2 control functions, the rest position in both normally open or normally closed are also offered. Various porting configurations including stand alone (BSPP), Factory standard manifold or Cetop 3 are available.

Applications :

Hydraulic power units in Nuclear Industry, Naval, Oil & Gas sector, Mining Industry, Water Treatment Plants, Desalination, Fire Protection Equipments, Food Industry Machinery.

- Flow Range : 0-30 lpm.

- Operating Pressure : 0 to 160 Bar

- Inlet Pressure : Max. 160 Bar

4-3 Directional Valves

A patented range of valves which control the directional flow of corrosive fluids in hydraulic systems. Designed For operation on tap water to EU directive 98/83/EC. The valves offer high efficiency with minimal energy input for actuation. Also available in 4/2 & 3/2 control functions. Various porting configurations including stand alone (BSPP), Factory standard manifold or Cetop 3 are available.

Applications :

Hydraulic power units in Nuclear Industry, Naval, Oil & Gas sector, Mining Industry, Water Treatment Plants, Desalination, Fire Protection Equipments, Food Industry Machinery.

- Flow Range : 0-30 lpm.

- Operating Pressure : 0 to 160 Bar

- Inlet Pressure : Max. 200 Bar

4-3 Manual valves

A patented range of valves which control the directional flow of corrosive fluids in hydraulic systems. Designed For operation on tap water to EU directive 98/83/EC. The valves offer high efficiency with minimal energy input for actuation. Also available in 4/2 & 3/2 control functions. Various porting configurations including stand alone (BSPP), Factory standard manifold or Cetop 3 are available.

Hydraulic power units in Nuclear Industry, Naval, Oil & Gas sector, Mining Industry, Water Treatment Plants, Desalination, Fire Protection Equipments, Food Industry Machinery.

Specifications :

- Flow Range : 0-30 lpm.

- Operating Pressure : 0 to 160 Bar

- Inlet Pressure : Max. 200 Bar

Actuation Cards

The directional control valves are supplied with a 12V DC coil*. The PCB ( Actuaton Card ) will control the duration of supply to ensure the maximum temperature of the coil is not exceeded. The solenoid should not be switched on/off continuously with a duty cycle shorter than 1 second.

- Solenoid coil actuation.

- Supply Voltage : 24V DC.

Check Valves

The check valves are a unique range of valves which are supplied in 316 stainless steel and high grade engineering polymer as standard, for operation on tap water to EU directive 98/83/EC. Available in 3 sizes, the range offers consistent performance even after lengthy periods of inactivity.

Applications :

Hydraulic power units in Nuclear Industry, Naval, Oil & Gas sector, Mining Industry, Water Treatment Plants, Desalination, Fire Protection Equipments, Food Industry Machinery.

- Flow Range : 30 to 200 lpm.

- Operating Pressure : 0.1 to 200 Bar

- Port Sizes : 1/4″,3/8″,1/2″,3/4″,1″ BSPP

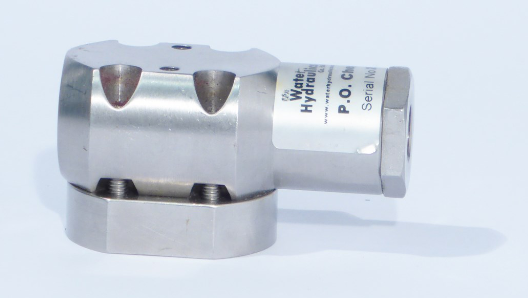

DN12 PO Check

Supplied in all 316 stainless steel construction, the DN12 PO Check can be actuated by multiple fluids. The valves are double sealed to ensure cross contamination does not occur. The PO Check offers bubble tight 100% seal operation for load or pressure holding applications and is available as stand alone or manifold mounted. The manifold block can be configured to offer double port checked functions.

Applications :

Hydraulic power units in Nuclear Industry, Naval, Oil & Gas sector, Mining Industry, Water Treatment Plants, Desalination, Fire Protection Equipments, Food Industry Machinery.

- Flow Range : 0-60 lpm.

- Operating Pressure : 0 to 160 Bar

- Inlet Pressure : Max. 160 Bar

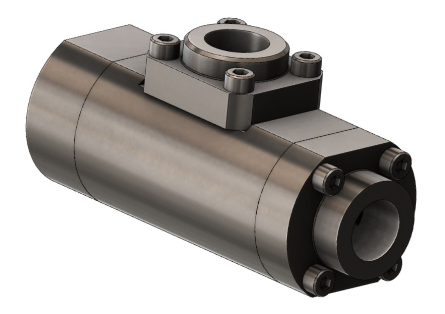

DN16 Directional Valves

Actuation by water, oil or compressed air pilot is possible on all configurations. The water version is also available with an integral DN3 solenoid operated pilot valve. ( Please note: adequate flow must be available to ensure the full travel of the valve is made ) The pilot piston can be sized to vary the pilot actuation pressure between 2 and 80 bar. The external pilot actuator is designed to operate at a pressure of 40 bar, although alternatives can be offered on request. For oil pilot, the actuator is supplied with a dual seal and air vent

design to prevent cross contamination of the fluids.

Applications :

Hydraulic power units in Nuclear Industry, Naval, Oil & Gas sector, Mining Industry, Water Treatment Plants, Desalination, Fire Protection Equipments, Food Industry Machinery.

- Flow Range : 0-140 lpm.

- Operating Pressure : 0 to 100 Bar

- Inlet Pressure : Max. 160 Bar

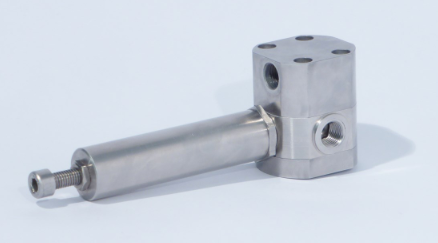

Electronic Flow Control Valves

The range of flow control valves are driven by a high accuracy stepper motor to ensure maximum precision for control by either open or closed loop means. The valves can be configured for manual/joystick input or to specific output speed/positional control. Closed loop feedback via output transducers is also possible with the use of an ST5 advanced micro-step programmable controller which is available with a 48V stable power supply if required. (Please see ST5 data sheet for further information). Additional output can also be offered for fail-safe configurations should such a function be necessary.

Applications :

Hydraulic power units in Nuclear Industry, Naval, Oil & Gas sector, Mining Industry, Water Treatment Plants, Desalination, Fire Protection Equipments, Food Industry Machinery.

- Flow Range : 0-30 lpm.

- Operating Pressure : 0 to 160 Bar

- Inlet Pressure : Max. 200 Bar

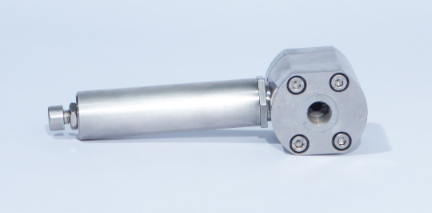

Electronic Pressure Control Valves

The range of proportional pressure control valves are driven by a high accuracy stepper motor to ensure maximum precision for control by either open or closed loop means. The valves can be configured for manual/joystick input or to specific output speed/positional control. Closed loop feedback via output transducers is also possible with the use of an ST5 advanced micro-step programmable controller which is available with a 48V stable power supply if required. (Please see ST5 data sheet for further information). Additional output can also be offered for fail-safe configurations should such a function be necessary.

Applications :

Hydraulic power units in Nuclear Industry, Naval, Oil & Gas sector, Mining Industry, Water Treatment Plants, Desalination, Fire Protection Equipments, Food Industry Machinery.

- Flow Range : DN6 : 0-30 lpm., DN12 : 5-100 lpm.

- Operating Pressure : 0 to 160 Bar

- Inlet Pressure : Max. 200 Bar

Flow Control Valves

Manufactured from 316 stainless steel and special engineering polymer selected for their corrosion resistance and resilience to flow erosion. Designed for operation on tap water to EU directive 98/83/EC without additive.

Applications :

Hydraulic power units in Nuclear Industry, Naval, Oil & Gas sector, Mining Industry, Water Treatment Plants, Desalination, Fire Protection Equipments, Food Industry Machinery.

- Max. Cv value in flow control direction : DN3 : 0.02., DN6 : 0.62

- Operating Pressure : 0.1 to 200 Bar

Hose Burst Valves

Manufactured from 316 stainless steel and special engineering polymer selected for their corrosion resistance and resilience to flow erosion. Designed for operation on tap water to EU directive 98/83/EC without additive.

Applications :

Hydraulic power units in Nuclear Industry, Naval, Oil & Gas sector, Mining Industry, Water Treatment Plants, Desalination, Fire Protection Equipments, Food Industry Machinery.

- Flow Range : DN3 : 30 lpm., DN6 : 50 lpm.

- Max. Cv value in flow control direction : DN3 : 0.02., DN6 : 0.62

- Operating Pressure : 0.1 to 200 Bar

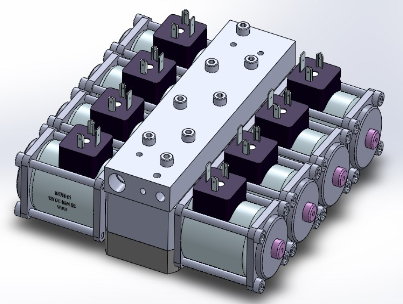

Manifolds

Available in 1 to 4 stations including with or without additional relief valve porting and produced in 316 stainless steel. The manifolds will accept the 3/2, 4/2 and 4/3 valve configurations in all actuation formations such as solenoid, pilot or manual.

Applications :

Hydraulic power units in Nuclear Industry, Naval, Oil & Gas sector, Mining Industry, Water Treatment Plants, Desalination, Fire Protection Equipments, Food Industry Machinery.

- Flow Range : Max. 30 lpm. W/o. integral PRV and 22 lpm with integral PRV.

- Number of stations : 1-4

Ordering code

PO Check Valves

Available as an individual valve or as a bolt on option to the 4/3 and 4/2 directional control valve, the PO Check offers bubble tight 100% seal operation for load or pressure holding applications.

Applications :

Hydraulic power units in Nuclear Industry, Naval, Oil & Gas sector, Mining Industry, Water Treatment Plants, Desalination, Fire Protection Equipments, Food Industry Machinery.

- Flow Range : 0-30 lpm.

- Operating Pressure : 0 to 160 Bar

- Inlet Pressure : Max. 200 Bar

Pressure compensating flow control valves

The pressure compensated flow control valve is designed to control the flow rate of tap drinking water in a hydraulic system. Fully adjustable between the specified ranges, the output flow can be regulated and maintained at a constant level irrespective of the output working pressure. The constant rate can be adjusted by allan key then loaded to prevent none desired alteration. The reverse flow gives a slightly restrictive orifice but vertically free for one way control.

Applications :

Hydraulic power units in Nuclear Industry, Naval, Oil & Gas sector, Mining Industry, Water Treatment Plants, Desalination, Fire Protection Equipments, Food Industry Machinery.

- Max. Cv value in flow control direction : DN3 : 0.2., DN6 : 0.7

- Operating Pressure : 5 to 200 Bar

Pressure Reducing Valves

A patented range of valves designed to control pressure in a hydraulic system using tap water to EU directive 98/83/EC. Designed specifically for fluids with low viscosity, the valve offers accurate control with high resistance to flow erosion experienced in pressure control applications.

Applications :

Hydraulic power units in Nuclear Industry, Naval, Oil & Gas sector, Mining Industry, Water Treatment Plants, Desalination, Fire Protection Equipments, Food Industry Machinery.

- Flow Range : 0-30 lpm.

- Pressure Setting Range : 30 Bar, 30 to 100 Bar, 70-160 Bar.

- Inlet Pressure : Max. 180 Bar

Relief Valves

A patented range of valves which can control the pressure of corrosive fluids in hydraulic systems. Designed specifically for fluids with low viscosity, the valve offers accurate control with high resistance to flow erosion experienced in pressure control applications. The valve fully conforms to the Pressure Equipment Directive and can include internal burst disc assemblies for safety applications.

Applications :

Hydraulic power units in Nuclear Industry, Naval, Oil & Gas sector, Mining Industry, Water Treatment Plants, Desalination, Fire Protection Equipments, Food Industry Machinery.

- Flow Range : DN3 : 0-10 lpm, DN6 : 0-30 lpm, DN12 : 0-120 lpm, DN16 : 0-450 lpm.

- Pressure Setting Range : 10-30 Bar, 25 to 100 Bar, 70-160 Bar, > to 160 Bar.

- Inlet Pressure : Max. 180 Bar

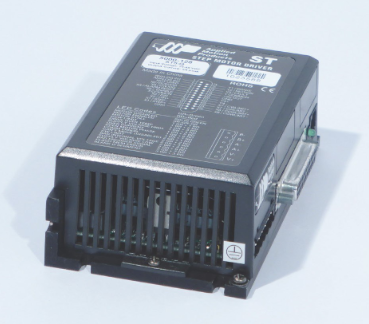

ST5-Q-NN Microstep Drive

The ST5-Q-NN stepper drive is a DC-powered microstepping drive for controlling two-phase, bipolar step motors. It offers advanced current control and a sophisticated 3rd generation anti-resonance algorithm that electronically dampens motor and system resonances to improve motor smoothness and usable torque over a wide speed range. The drive also employs electronic torque ripple smoothing and microstep emulation to greatly reduce motor noise and vibration. The drive must be powered from 24-48 VDC and can output up to 5.0 A/phase (peak-of-sine) to the step motor. Over-voltage, over-temperature and over-current protection features prevent damage while running in adverse conditions. The drive is complemented by a specifically matched set of NEMA 11 through NEMA 23 frame stepper motors.

- Supply Voltage : 24-48 VDC

- Control Modes : Step & Direction, Velocity (Oscillator), Streaming Commands, Analog Positioning, Encoder Following, Q Programming, SiNet Hub Compatible, Modbus RTU.

Zone Valves

A patented range of manifold mounted zone valves manufactured in 316 stainless steel for use within the high pressure water mist industry. The zone valve can be supplied fitted into a one to five station manifold, with pilot and solenoid operation. Various porting configurations are available.

Applications :

Hydraulic power units in Nuclear Industry, Naval, Oil & Gas sector, Mining Industry, Water Treatment Plants, Desalination, Fire Protection Equipments, Food Industry Machinery.

- Flow Range : 0-60 lpm.

- Operating Pressure : Max. 160 Bar

- Sizes available : DN3, DN9, DN25.

Solenoid :

- Solenoid actuated 12 or 24 volts for independent zone operation.

- Coil power 32 watts.

Pilot :

- Pilot actuated for independent zone operation.

- Pilot pressure 10 to 40 bar.

- ATEX approved.